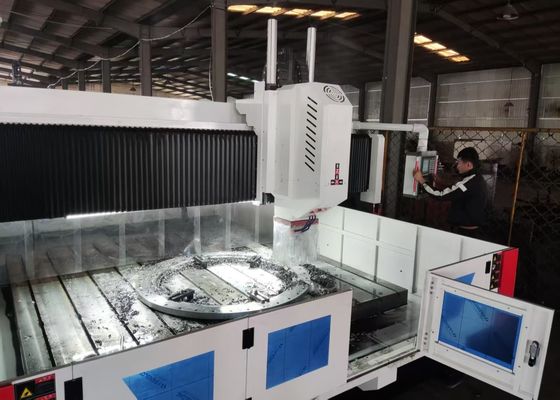

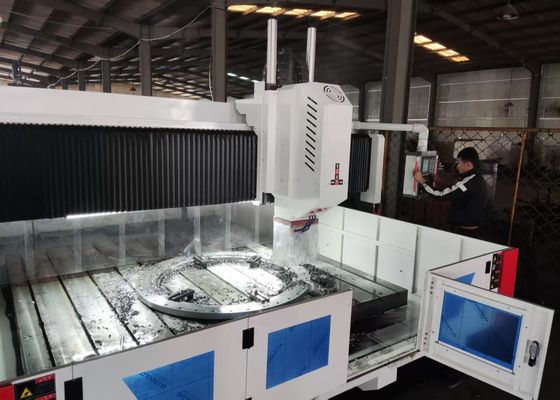

13000x1000mm kích thước đồ đạc CNC máy khoan và máy mài M3-M10 đường kính chạm

Ứng dụng:

Thiết bị khoan và mài kim loại mảng cổng CNC này chủ yếu được thiết kế để thực hiện các quy trình khoan, khoang, chạm, mài và khoan trên tấm và các thành phần cấu trúc.Nó cung cấp hiệu suất khoan lỗ hiệu quả cho các mảnh làm việc bao gồm cả các miếng lót, đĩa, vòng và tấm với độ dày nằm trong phạm vi hoạt động hiệu quả của nó. có khả năng gia công qua lỗ và lỗ mù,nó tương thích với cả các thành phần bằng vật liệu đơn và vật liệu tổng hợpVới công nghệ điều khiển kỹ thuật số, công cụ máy đảm bảo sự tiện lợi hoạt động đặc biệt.sản xuất chính xác cao các loại sản phẩm khác nhau trong các kịch bản sản xuất quy mô lớn.

Thông số kỹ thuật:

| Kích thước đồ đạc |

LxW |

13000x1000 mm |

| Chiều cao của cổng |

600 mm (Nó cũng có thể được xác định theo cơ sở)

|

| Bàn làm việc |

Chiều rộng khe T |

28mm |

| Đầu công suất khoan |

Qty. |

2 |

| Máy thu tròn |

BT2văn hóa |

|

Chiều kính khoan tối đa

(Thép carbon thông thường)

|

Φ30 mm |

| Chiều kính khớp |

M3-M10 |

| Tốc độ xoắn |

30~6000 vòng/phút |

| Sức mạnh động cơ trục phụ |

7.5kW |

| Khoảng cách từ đầu dưới của trục đến bàn làm việc |

200-600mm |

|

Chuyển động bên của đầu động cơ(Trục X)

|

Max.horizontal stroke |

1000 mm |

| Tốc độ di chuyển bên |

0 ~ 8 r/min |

| Năng lượng động cơ servo cho chuyển động bên |

2.4kW |

|

Chuyển động theo chiều dọc của gantry (Trục Y)

|

Max. feed stroke |

13000 mm |

| Tốc độ di chuyển thức ăn |

0 ~ 8 m/min |

| Năng lượng động cơ phụ cấp |

2x2,4kW |

| Động cơ cung cấp ram theo chiều dọc (trục Z) |

Tối đa. |

300 mm |

| Tốc độ di chuyển |

0 ~ 5 m/min |

| Sức mạnh của động cơ phụ trợ |

7.5kW (động) |

| Độ chính xác định vị trí ba trục |

X/Y/Z/A/B/C |

± 0,015/1000mm |

| Độ chính xác định vị ba trục lặp lại |

X/Y/Z/A/B/C |

±0,01/1000mm |

| Kích thước tổng thể |

LxWxH |

13000x3000x2500 mm |

Tính năng sản phẩm

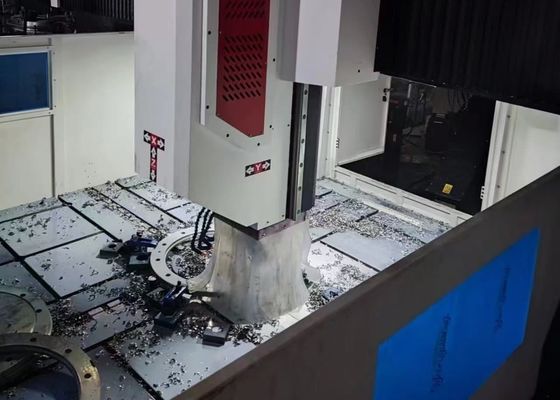

1. giường và bàn làm việc:

Ghế và bàn làm việc được chế tạo như các sản phẩm đúc tích hợp sử dụng sắt xám (HT250), trải qua các phương pháp điều trị sơn và lão hóa thứ cấp,và hoàn thành bằng gia công chính xác để đảm bảo độ cứng động và tĩnh vượt trội, đảm bảo không có biến dạng. bề mặt bàn làm việc được trang bị các khe T được chế biến chính xác trong một bố trí tối ưu, tạo điều kiện cho việc kẹp mảnh làm việc an toàn.Cơ sở giường được trang bị hai đường dẫn tuyến tính chính xác cao trên mỗi bên, đảm bảo sự phân phối lực đồng đều trên các đường trượt và tăng đáng kể độ cứng của máy công cụ cũng như sức đề kháng kéo và nén của nó.Hệ thống lái xe sử dụng động cơ AC servo kết hợp với các ốc vít chính xác cho hoạt động hai bên, cho phép các gantry để đi qua dọc theo trục Y. Bốc điều chỉnh được đặt chiến lược trên cơ sở giường,cho phép hiệu chuẩn đơn giản của giường và bàn làm việc.

2. Đường cổng di động:

Chiếc lưng có thể di chuyển là một thành phần cấu trúc sắt đúc chính xác, tích hợp với bốn slide hướng dẫn tuyến tính CNC chịu tải trọng cao, một tập hợp vít bóng chính xác,và một máy giảm độ chính xác cao của hành tinh kết nối với một động cơ servoNó cũng được trang bị một xi lanh cân bằng nitơ, phục vụ để cân bằng trọng lượng của đầu công suất, giảm tải trọng trên vít, kéo dài tuổi thọ của vít,và lái xe đầu sức mạnh khoan để di chuyển dọc theo trục ZCấu hình này cho phép các hoạt động như tiến bộ nhanh, cấp thức ăn làm việc, thu hồi nhanh và dừng lại, trong khi kết hợp chức năng phá vỡ chip tự động, loại bỏ chip và tạm dừng.

3. Đầu máy khoan:

Đầu công suất khoan được trang bị một động cơ xoắn tay servo chuyên dụng,sử dụng một dây đai đồng bộ có răng để giảm tốc độ và khuếch đại mô-men xoắn để điều khiển một trục chính xác chuyên biệtVòng trục kết hợp một sắp xếp vòng bi góc Nhật Bản sáu hàng (bốn ở phía trước, hai ở phía sau) để cho phép điều chỉnh tốc độ không bước.Nó được trang bị một hệ thống thay đổi công cụ khí nén, tạo điều kiện thay thế công cụ nhanh chóng và thuận tiện.Các trục X và Y có khả năng liên kết và sử dụng điều khiển vòng tròn bán đóng để đạt được các chức năng can thiệp tuyến tính và tròn. Đầu trục được thiết kế với một lỗ cong BT50 và tích hợp với một khớp quay tốc độ cao, cho phép gia công khoan U tốc độ cao với làm mát bằng nước trung tâm.

5Hệ thống truyền tải:

Kết hợp các đường ray hướng dẫn nhập khẩu từ Đài Loan và thiết kế trượt chính xác cao, hệ thống truyền tải đảm bảo hoạt động trơn tru trong khi tăng khả năng xử lý tải trọng nặng.

Máy khoan, đánh dấu và mài CNC kiểu gantry cho vòm và thép cacbon là một thiết bị công nghiệp hiệu suất cao,được thiết kế tỉ mỉ để gia công chính xác các thành phần loại tấm và các bộ phận cấu trúcThiết bị này được thiết kế tùy chỉnh để xử lý các mảnh làm việc như vòm, đĩa, vòng và tấm phẳng,với một yêu cầu cốt lõi rằng độ dày của các mảnh làm việc này tuân thủ nghiêm ngặt phạm vi gia công hiệu quả được chỉ định của máy.

Trong các xưởng xây dựng thép, thiết bị này cung cấp khoan và mài chính xác cho các tấm cấu trúc và các thành phần kết nối,đặt nền tảng vững chắc cho việc lắp ráp ổn định các khung thépTrong lĩnh vực năng lượng gió,nó cung cấp các giải pháp gia công chính xác cao cho tháp tuabin gió và vòm (một quy trình thiết yếu đảm bảo các thành phần này có thể chịu được các điều kiện môi trường khắc nghiệt)Đối với các dự án xây dựng cầu, các thiết bị xử lý các vạch cầu và hỗ trợ hỗ trợ, tạo điều kiện cho sự hình thành ổn định,Các kết nối bền được thiết kế để chịu tải năng động trong suốt cuộc sống dịch vụ kéo dài của cầu.