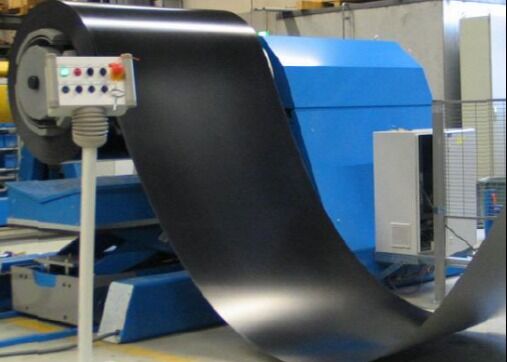

Dây chuyền sản xuất xả cuộn, đột lỗ, chấn nguội khay cáp tự động 7000 Kg

Giới thiệu sản phẩm:

Dây chuyền sản xuất xả cuộn, đột lỗ và chấn nguội khay cáp tự động có thể đạt được một tấm đơn ban đầu của đa quy trình, sản xuất liên tục, thiết lập xả cuộn, san phẳng, đột lỗ, tạo hình, cắt trong một sản xuất liên tục, để sản phẩm có hình thức tiêu chuẩn, việc lắp đặt lỗ đục nhất quán rất dễ dàng. Dây chuyền sản xuất có tốc độ sản xuất cao, đột lỗ trực tuyến và sản xuất tạo hình liên tục, dễ vận hành và sử dụng ít nhân công.

Cấu hình sản phẩm:

| Nguyên vật liệu |

Tấm cán nguội Q235 |

| Đường kính ngoài cuộn thép phù hợp |

Ф1200 mm |

| Đường kính trong cuộn thép phù hợp |

Ф508mm |

| Chiều rộng nguyên vật liệu |

<1050mm |

| Độ dày nguyên vật liệu |

1~3mm |

| Trọng lượng cuộn thép đơn |

≤7000 kg |

| Kích thước khay cáp |

rộng 100~500;cao:50~200 |

| Tốc độ làm việc hiệu quả |

3~10m/phút |

Quy trình sản xuất:

Xả cuộn-san phẳng-vòng vật liệu—bộ nạp servo—máy đột đa trạm (cắt)--máy tạo hình chính—đầu ra hồ sơ cuối cùng

Các thành phần chính

Bệ truyền động 1 bộ

Ứng dụng: vận chuyển tấm đột đến máy tạo hình

Cấu trúc: Nó áp dụng băng tải với thiết bị dẫn hướng, chủ yếu bao gồm khung, thiết bị truyền động, băng tải, thiết bị điều chỉnh chiều rộng, thiết bị dẫn hướng, v.v. Tốc độ nạp có thể điều chỉnh vô hạn, phù hợp với tốc độ của máy tạo hình.

| Tốc độ nạp tối đa |

15m/phút |

| Chiều rộng nạp cho phép tối đa |

≤1050mm |

| Công suất động cơ |

7.5kw |

| Chiều dài nạp |

16000mm |

Máy tạo hình điều chỉnh được dạng cantilever -1 bộ

Ứng dụng: Được sử dụng để cán hình dạng tấm thành phẩm theo yêu cầu thành hình dạng mặt cắt ngang cuối cùng thông qua quá trình uốn cuộn.

Cấu trúc: Bộ phận tạo hình áp dụng chế độ máy tạo hình cantilever. Được điều khiển bởi động cơ, bộ giảm tốc và bánh răng côn xoắn.

Khi sản xuất các sản phẩm có chiều rộng đáy và chiều cao eo khác nhau, bạn chỉ cần đặt các thông số trên màn hình cảm ứng, rất tiện lợi, nhanh chóng và đáng tin cậy.

Con lăn tạo hình được thiết kế bởi phần mềm chuyên nghiệp. Vật liệu được làm bằng thép khuôn chất lượng cao Cr12 và độ cứng sau khi tôi là HRC58~62 (tương đương với vật liệu D2/D3 của Mỹ). Bề mặt của con lăn được đánh bóng sau khi hoàn thiện. Con lăn có độ chính xác cao và tuổi thọ dài.

Bộ phận tạo hình chính chứa hai máy tạo hình. Đế của máy tạo hình được trang bị một thiết bị di chuyển, có thể di chuyển theo chiều dọc trên các thanh ray dẫn hướng được cài đặt sẵn của bạn. Hai máy tạo hình và một máy để sản xuất xà gồ hình chữ C,

Thông số: Lượt tạo hình: 10+12 lượt

| Đường kính trục của máy tạo hình |

φ100mm (tùy thuộc vào thiết kế cuối cùng) |

| Tổng công suất động cơ |

khoảng 30KW (tùy thuộc vào thiết kế cuối cùng) |

| Thương hiệu động cơ |

Siemens Bader |

| Tốc độ tuyến tính tối đa |

5~15m/phút |

1 bộ giá đỡ không có động cơ (tổng chiều dài 12 mét)

Giá đỡ ở chế độ không có động cơ, với tổng cộng hai phần và mỗi phần dài 6 mét. Giá đỡ vật liệu là một cấu trúc có thể tháo rời, thuận tiện cho việc vận chuyển và sử dụng ở những nơi khác nhau.

Hệ thống thủy lực 1 bộ

Ứng dụng: Cung cấp hỗ trợ năng lượng cho việc xả cuộn và đột lỗ.

Cấu trúc: Cấu trúc kết hợp của bơm và bộ tích lũy được áp dụng, và hành động đột và cắt nhanh chóng, và tốc độ của dây chuyền sản xuất được cải thiện. Bộ làm mát bằng không khí được sử dụng để tản nhiệt để đáp ứng các yêu cầu về công việc và sản xuất dưới tải trọng cao và nhiệt độ cao hơn. Hệ thống thủy lực là một hệ thống thủy lực nhanh, phù hợp với các dây chuyền sản xuất chấn nguội đột lỗ tốc độ cao, tạo hình cuộn và cắt. Các thành phần thủy lực chính áp dụng các sản phẩm Bắc Kinh Huade.

Các thành phần chính là: bơm dầu, động cơ, van thủy lực, van điện từ, bộ lọc và thùng dầu thủy lực, v.v.

Bộ điều khiển điện -1 bộ

Toàn bộ dây chuyền áp dụng chế độ điều khiển người-máy kết hợp PLC và màn hình cảm ứng. Các thông số kỹ thuật, số lượng và thông số hệ thống của các bộ phận có thể được thiết lập thông qua màn hình cảm ứng và nhiều bộ hướng dẫn vận hành có thể được lưu trữ cùng một lúc. Nó có mức độ tự động hóa cao. Nó có chức năng báo động trong trường hợp có bất thường trong dây chuyền sản xuất. Hoạt động của toàn bộ dây chuyền sản xuất có thể được theo dõi thông qua hệ thống điều khiển. Sau khi mất điện hoặc tắt máy bất thường, quá trình có thể được tiếp tục theo các thông số làm việc đã được thiết lập trước đó.